BEONE Lighting knows that the high quality lighting of space has a very high demand for color temperature consistency,

and understand the phenomenon that color temperature is inconsistent with the present market LED, which is critcized

by owners and designers. So, BEONE selects the LED chips suppliers having world leading the color temperature

consistency, Meanwhile,BEONE Lighting strictly categorize and manage different batches of chips to ensure the

chips for the same sites using the same batch.

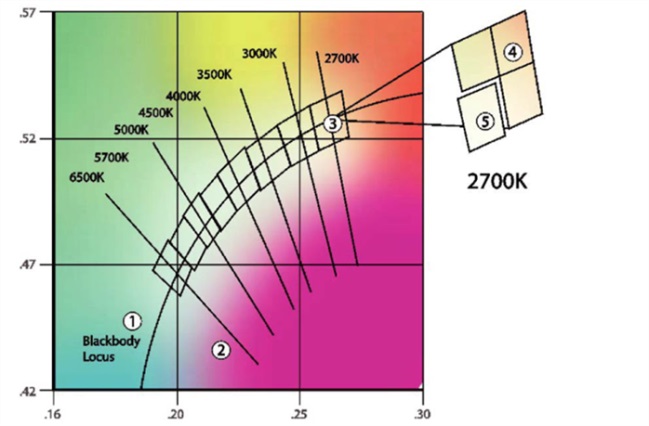

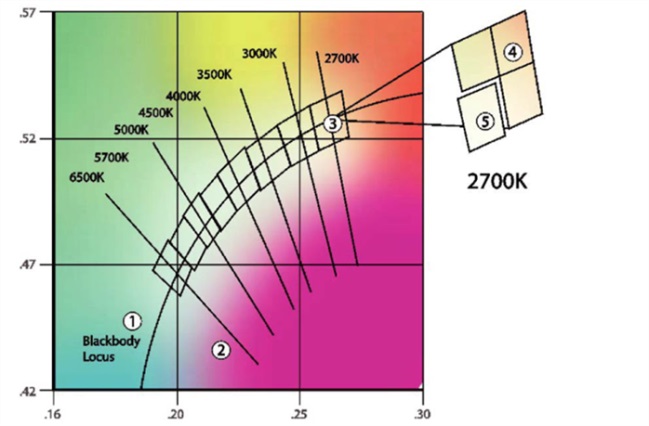

The most challenging aspect in the production of LED is the production of consistent and accurate white. Bin setting refers

to dividing different similar white LED into a group.This approach rules to United States ANSI standard frameworks which

allow tolerance.Some LED manufacturers adopt more restrictive division, only allowing very little chromatic aberration.

BEONE adopts much smaller bin area exceeding ANSI standards and makes sure high quality color of LED lamps.

Bin Explanation: When the LED glows, whether warm white or cool white, there will always be a little inconsistent in the

specified color temperature of the light.

A. The curved black lines on above diagram representative white spectra.

B. Intersecting straight lines represent the color temperature range.

C. In order to make each range to be as close as possible to the same color,

ANSI standards set the tolerance zone. All the LEDS belong to this zone

are classified as a specific color temperature.

D. You can distinguish the color aberration in the same bin. ANSI standard

tolerance illustrates the challenge for LED chip production consistency.

E.Once you separate out the simaller bin area,chromatic aberration is much smaller.

(Note: Although the color temperature consistency will increase production cost, different LED chip manufacturers can produce

chips with smaller bin. The range of each bin may differ by different LED manufacturers. Under the micro- district, the color

temperature consistency from the same batch is better. Usually there will be color difference between different batches)